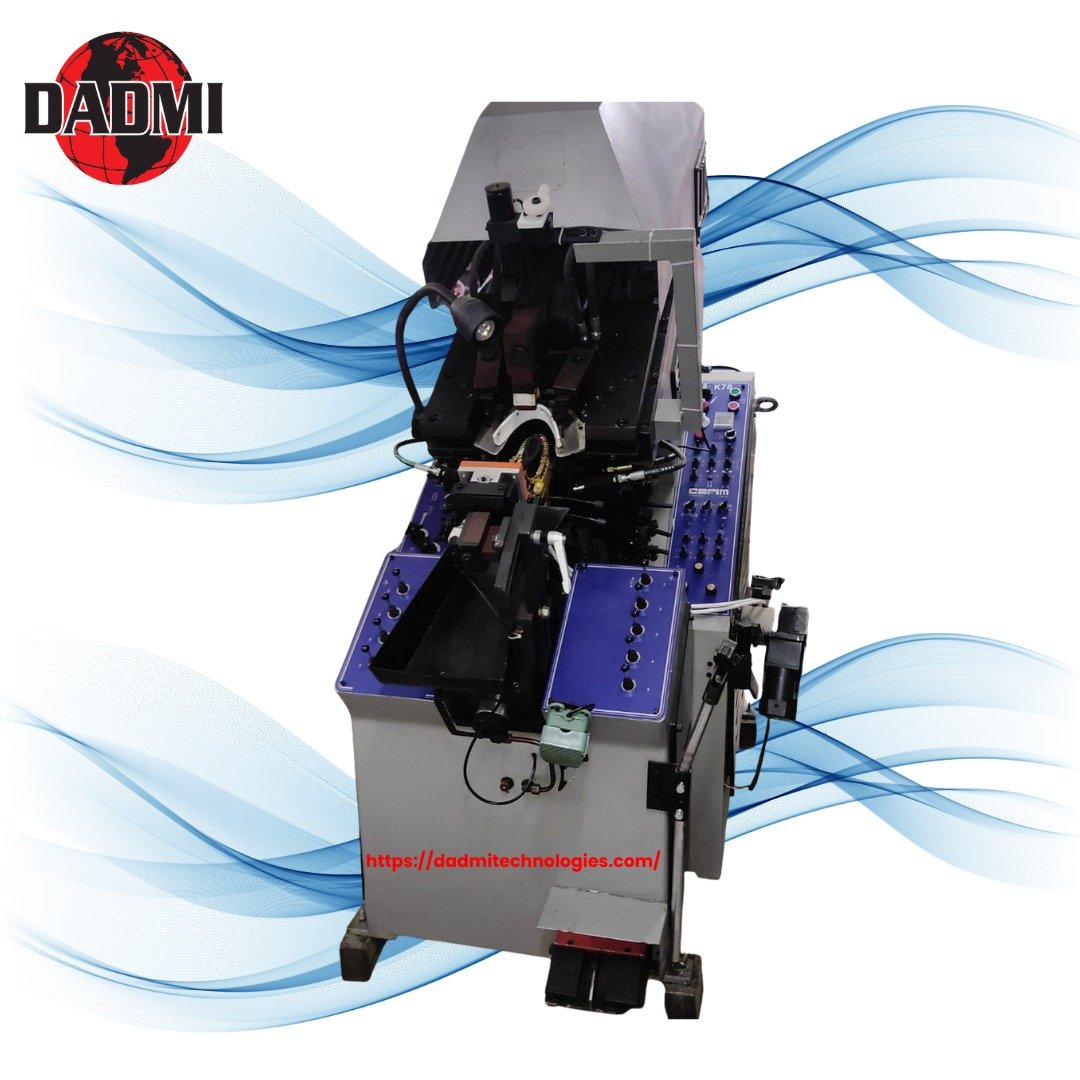

Auto Cement: Streamlines the cementing process, automating the application of adhesive for improved efficiency and uniform bonding.

Even and Close Attachment: It features a band and wipers that ensure the uppers are attached to the lasts evenly and closely, resulting in improved shoe quality.

Adjustable Pressure: Operators can adjust the pressure for pressing the toe part of the shoe, preventing over-lasting and excessive pulling down of the uppers. This customization enhances precision in the lasting process.

Independent Pincers: The machine is equipped with 9 independent pincers that can be adjusted to fit various shoe toe shapes. It also includes automatic balancing and descending mechanisms for improved quality and increased production capacity.

Last Support Plate: To prevent lasts from slipping off during the process, the machine has a rising mechanism and heel supporter integrated into the last support plate.

Customizable Settings: Various switches and adjustments are available to customize the machine for different shoe sizes and operations, ensuring versatility in production.

Cement Applicator: Additional wipers and a cement applicator can be adjusted to ensure perfect attachment of the toe upper to the last.

Independent Adjustment: The pincers and fixed plate can be adjusted independently to optimize the attachment of uppers to lasts, accommodating various shoe designs

Specifications

- Dimension (LxWxH) 1660 x 980 x 1980mm

- Net Weight (N.W) 1200 kgs

- Capacity 1500 Pairs / 8 Hours

- Heating 1500W

- Power 2HP

- Voltage 380V/50HZ

- Oil Pressure 30-50kg/CM2

- Hydraulic Oil Capacity 120 Liters

Machine Maintenance & Operation Guidelines

- Regular Cleaning and Lubrication: Regularly clean and lubricate the machine to prevent dust and dirt buildup, which can cause damage or malfunctions.

- Routine Inspections:Conduct routine inspections to identify signs of wear, tear, or damage and address them promptly.

- Adherence to Schedule:Adhere to the manufacturer’s recommended maintenance schedule, including oil changes and filter replacements.

- Proper Use:Use the machine only for its intended purpose and within its stated capacity.

- Comprehensive Training:Provide comprehensive training to all operators on safe and effective machine operation, emphasizing proper maintenance procedures.

Machine Safety & Operation

- Electrical Safety:Ensure proper grounding of the machine to prevent electrical hazards.

- Authorized Use:Only authorize and train individuals before allowing them to operate the equipment.

- Moving Parts:Keep hands and loose clothing away from moving machine parts to avoid injury.

- Maintenance:Always power off and disconnect the machine from the power source before performing maintenance or repairs.

Reviews

There are no reviews yet.