Description

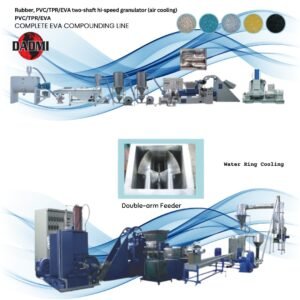

- The Roll Calendar Machine is a heavy-duty, high-precision industrial solution designed for producing smooth, uniform sheets with accurate thickness control. Engineered for consistent performance and long service life, this machine is widely used in the processing of rubber, EVA, PVC, and other polymer materials across footwear, automotive, and general manufacturing industries.

- Equipped with hardened and polished rollers, the machine ensures excellent surface finish and uniform material distribution. The robust steel frame minimizes vibration during operation, resulting in stable performance and high-quality output even during continuous production. Adjustable roller gaps allow precise control over sheet thickness, meeting diverse production requirements with ease.

- The integrated control panel enables simple and safe operation, while the efficient drive system ensures smooth rolling, reduced energy consumption, and minimal maintenance. Designed with operator safety in mind, the Roll Calendar Machine includes protective covers and easy-access controls for secure and user-friendly handling.

- Ideal for manufacturers seeking reliability, accuracy, and productivity, this Roll Calendar Machine delivers consistent results, improved workflow efficiency, and superior sheet quality for demanding industrial applications.

Uses of Roll Calendar Machine

- Manufacturing uniform rubber sheets for footwear soles and industrial applications

- Producing EVA sheets for slippers, sandals, and shoe components

- Calendaring PVC sheets for mats, flooring, and flexible products

- Processing polymer and plastic sheets with smooth surface finish

- Laminating and finishing sheets for automotive and industrial parts

- Thickness control and surface smoothing of compound materials

- Continuous sheet production for high-volume manufacturing

Specifications

- Applications Rubber, EVA, PVC, and polymer sheet processing

Roller Material Hardened and polished steel

Roller Adjustment Manual / Adjustable gap control

Sheet Thickness Customizable as per production requirement

Drive System High-efficiency motor with smooth transmission

Control System User-friendly electrical control panel

Construction Heavy-duty steel frame for vibration-free operation

Power Supply As per customer requirement

Customization Available as per material and production capacity

Maintenance Instructions

- Clean rollers and conveyor belt regularly to prevent material buildup and ensure smooth operation.

- Lubricate bearings, gears, and moving parts as per the maintenance schedule to reduce wear.

- Check roller alignment and gap settings periodically for consistent sheet thickness.

- Inspect electrical connections, control panel, and switches to ensure proper functioning.

- Replace worn-out rollers, belts, or seals promptly to maintain production quality.

- Keep the machine dry and free from dust for longer service life and reliable performance.

Safety Guidelines

- Operate the machine only by trained and authorized personnel.

- Ensure all safety guards and protective covers are securely in place before operation.

- Do not place hands or tools near rotating rollers during operation.

- Use emergency stop buttons immediately in case of abnormal noise or malfunction.

- Wear appropriate personal protective equipment (PPE) such as gloves and safety shoes.

- Disconnect power supply before cleaning, maintenance, or adjustments.

Reviews

There are no reviews yet.