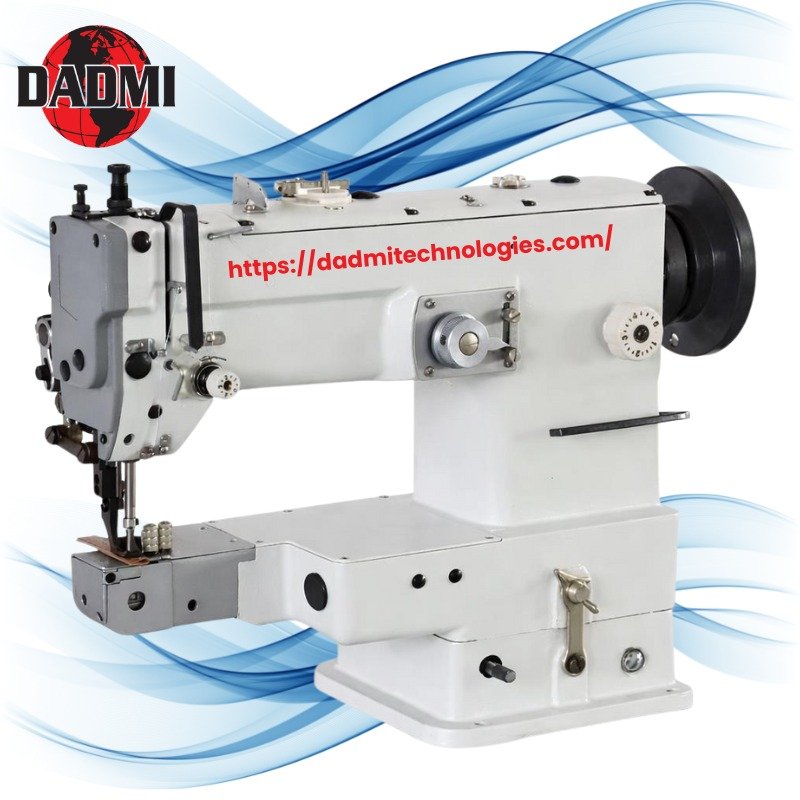

This industrial Cylinder Bed Zigzag Sewing Machine is a versatile and high-performance solution designed for precision binding and zigzag stitching applications. Built with a durable cylinder-bed structure, it allows smooth handling of curved, tubular, and hard-to-reach areas, making it ideal for shoe uppers, bags, linings, orthopedic products, and upholstery work.

Equipped with a single-needle zigzag stitching mechanism, the machine delivers strong, flexible, and uniform stitches that enhance seam durability while maintaining fabric elasticity. The zigzag stitch is especially effective for tape binding, edge finishing, and decorative stitching, ensuring clean and professional results.

Its robust construction, smooth operation, and adjustable stitch controls make it suitable for continuous industrial use. Widely adopted in the footwear, textile, and upholstery industries, this machine offers reliable performance, consistent stitch quality, and excellent adaptability across a wide range of materials.

Machine Type Cylinder Bed Zigzag Sewing Machine

Model No. FES: 333Z

Brand Name FEISU

Stitch Type Single Needle Zigzag

Application Tape Binding, Edge Binding, Decorative Zigzag

Needle Type DP×17 / DB×1 (As per requirement)

Stitch Width Adjustable

Stitch Length Adjustable

Motor Type Clutch Motor / Servo Motor (Optional)

Operating Speed Up to 2,000–2,500 stitches per minute

Suitable Materials Leather, Synthetic, Textile, Upholstery Fabrics

Power Requirement 220V / 50–60 Hz

Maintenance & Lubrication

Proper maintenance and regular lubrication are essential to ensure smooth operation, consistent stitch quality, and long service life of the machine.

- Daily Cleaning: Clean the needle area, presser foot, feed mechanism, and cylinder bed at the end of each shift to remove dust, lint, and thread residues.

- Lubrication: Apply sewing machine oil to all designated lubrication points as recommended. Regular lubrication reduces friction, prevents overheating, and ensures smooth movement of internal components.

- Oil Level Check: Check the oil level periodically and refill if required using high-quality sewing machine oil. Avoid over-lubrication.

- Needle & Thread Care: Replace worn or bent needles promptly and ensure correct needle installation. Use good-quality thread suitable for the material being sewn.

- Fastener Inspection: Periodically check screws, bolts, and moving parts to ensure they are properly tightened and aligned.

- Professional Servicing: Schedule regular inspections and servicing by a qualified technician to maintain optimal performance and prevent unexpected downtime.

Safety Guidelines

- Operate the machine only by trained personnel.

- Ensure proper electrical grounding and correct voltage supply.

- Keep hands, hair, and loose clothing away from the needle and moving parts.

- Switch off the power before cleaning, adjusting, or servicing the machine.

- Do not operate the machine with damaged or loose parts.

- Use only recommended needles, threads, and accessories.

- Keep the work area clean, dry, and well-lit.

- Stop the machine immediately if abnormal noise or vibration occurs.

- Keep children and unauthorized persons away from the machine.

Reviews

There are no reviews yet.