Extruder Machines are advanced industrial equipment designed to process raw materials by forcing them through a specially shaped die, producing uniform shapes, sheets, tubes, or pellets. Widely used in the plastics, rubber, food, and chemical industries, these machines ensure consistent quality, precise dimensions, and high production efficiency.

Equipped with robust motors, precision screws, and temperature-controlled barrels, extruder machines can handle a variety of materials such as thermoplastics, thermosetting polymers, elastomers, and even food-grade products. They offer features like continuous operation, customizable output, and energy-efficient performance.

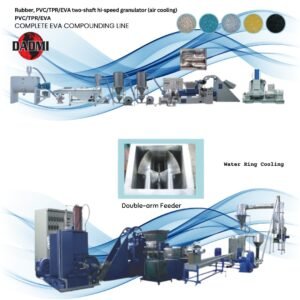

Modern extruders come in various types, including single-screw, twin-screw, and multi-layer extruders, each suited for specific applications such as compounding, mixing, or co-extrusion. With automated controls and advanced safety mechanisms, these machines minimize downtime and reduce manual intervention, making them essential for large-scale industrial manufacturing.

Key Benefits:

-

High precision and consistent output

-

Capable of handling diverse materials

-

Energy-efficient and cost-effective

-

Suitable for continuous large-scale production

-

Easy integration with downstream processing equipment

Extruder machines are a cornerstone in modern manufacturing, enabling industries to create high-quality products with complex shapes and superior material properties

Reviews

There are no reviews yet.