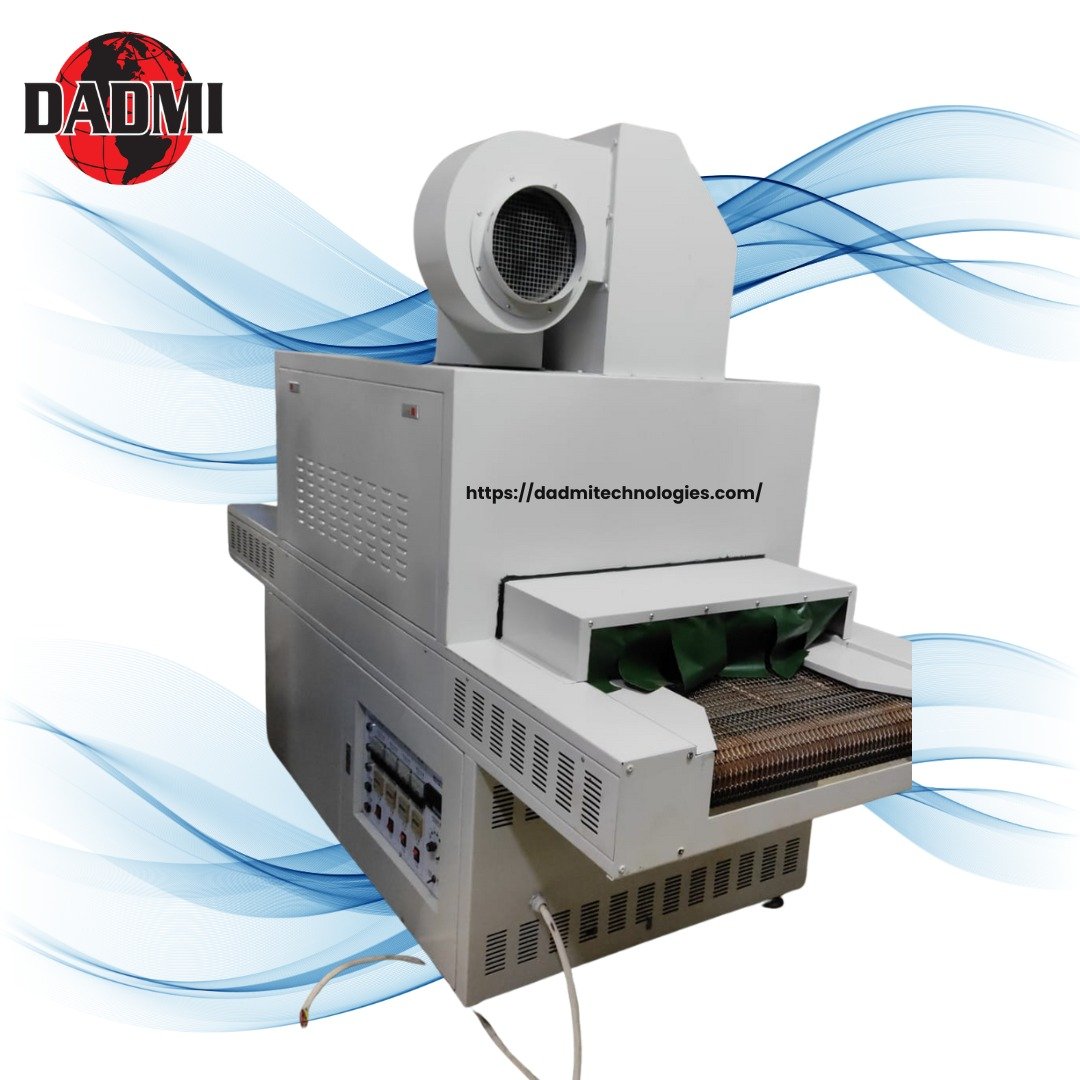

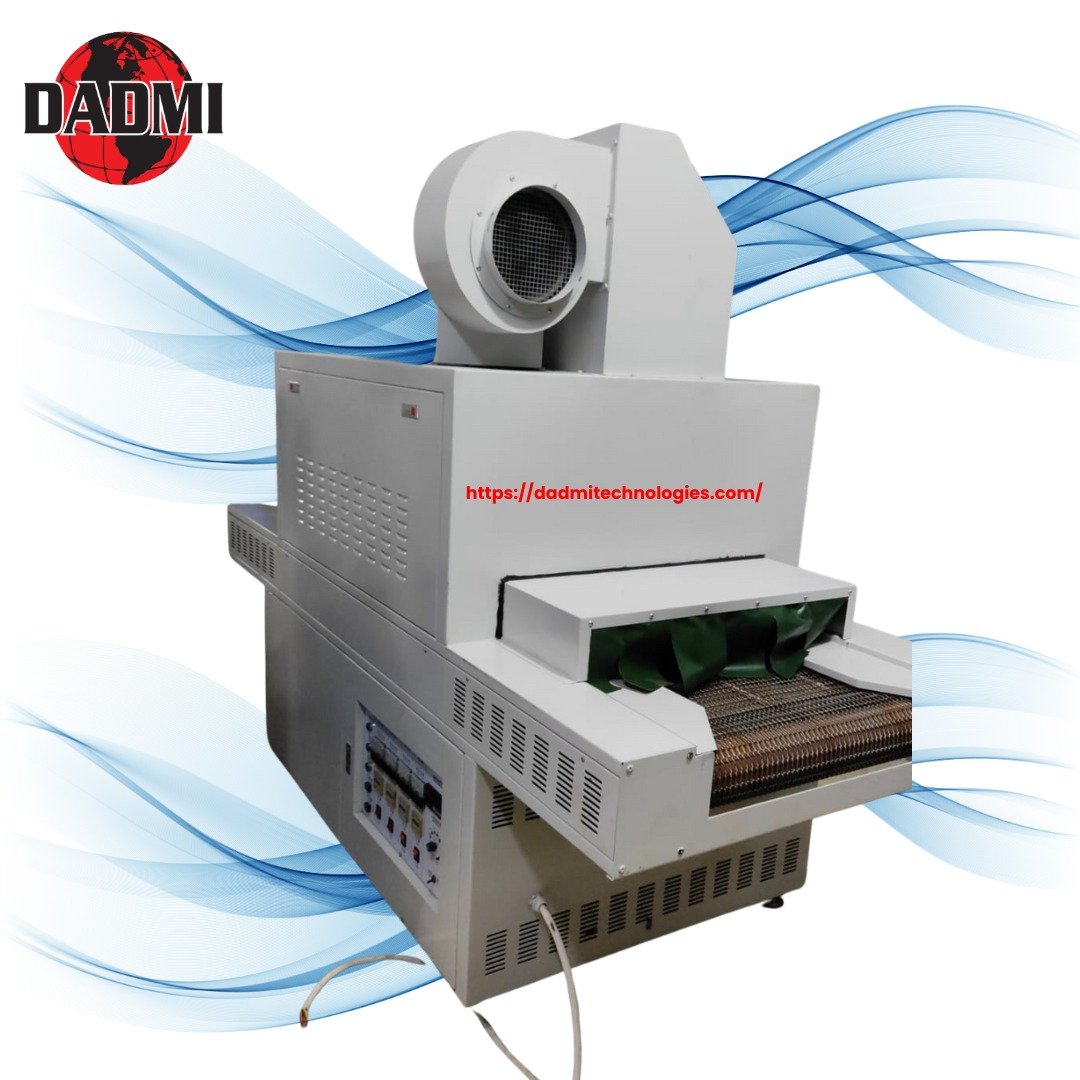

Key Features

- Multiple Independent UV Systems:The oven is equipped with four sets of 8KW independent control UV systems that can be used interchangeably. This feature extends the service life of UV lamps and provides flexibility in the curing process.

- Teflon Belt:The oven utilizes a Teflon belt that can withstand high temperatures, ensuring efficient material transport through the curing process.

- Variable Conveyor Speed:The conveyor is driven by a well-known motor with step less speed adjustment, allowing precise control over conveyor speed according to the product being processed.

- High-Quality UV Lamps:The UV lamps feature a high-quality light source with a long life span. They start instantly, rapidly reaching the desired UV brightness for efficient curing.

- Precision Control:Electrical components imported from Taiwan, including transformers and starters, provide precise control and long-lasting performance.

- Ventilation System:The oven is equipped with a ventilation function that quickly distributes heat, maintaining a low temperature inside the oven. This minimizes product deformation and improves lamp efficiency.

- Reverse Ventilation:The UV oven offers both ventilation and air suction in reverse and simultaneously. This feature ensures optimal UV curing for thin materials like paper, PVC film, soft PCB, and UV silicone gel.

Specifications

- Model: DS210U

- Inlet Length: 620mm

- Inlet Height: 100mm

- Oven Length: 1200mm

- Outlet Length: 620mm

- Belt Width: 420mm

- UV Lamp: 8KW/4 pcs

- Height from Ground to Belt: 800mm

- Power (V/kW): 220V Single Phase

Maintenance Guidelines

- Regular Cleaning:Keep the UV Sole Activating Machine clean by removing dust and debris from the conveyor belt, lamp housing, and ventilation system. Use appropriate cleaning materials and follow safety guidelines.

- UV Lamp Replacement:Monitor the UV lamps for signs of wear or diminished performance. Replace lamps as recommended by the manufacturer to maintain consistent curing results.

- Teflon Belt Inspection:Check the condition of the Teflon conveyor belt If it shows signs of wear, fraying, or damage, replace it promptly to ensure smooth material transport and prevent belt-related issues.

- Motor Maintenance:Maintain the conveyor motor by lubricating it as per the manufacturer’s recommendations to ensure smooth and reliable conveyor operation.

- Electrical Component Inspection:Periodically inspect electrical components, such as transformers and starters, for signs of wear or damage. Replace any faulty components promptly to ensure precise control and safety.

- Ventilation System:Clean and inspect the ventilation system to ensure it operates efficiently. Address any issues with airflow or cooling promptly to prevent overheating and material deformation.

- Safety Device Testing:Regularly test and verify the proper functioning of safety devices, including alarm systems and emergency stop.

Safety Guidelines for UV Sole Activating Machine Operation

- Training:Ensure that all personnel operating the UV Sole Activating Machineare trained in its safe operation and emergency procedures. Proper training significantly reduces the risk of accidents.

- Personal Protective Equipment (PPE):Provide and require operators to wear appropriate PPE, including safety glasses and protective gloves, to protect against UV exposure and potential hazards.

- UV Exposure:Avoid direct exposure to UV light emitted by the lamps. Implement safety measures like UV-blocking screens or curtains to prevent skin and eye exposure.

- Proper Grounding:Ensure that the UV Sole Activating Machine and all related equipment are properly grounded to prevent electrical hazards.

- Emergency Stop:Ensure that operators are familiar with the location and use of the emergency stop In case of any malfunction or safety concern, the oven should be stopped immediately.

- Maintenance Procedures:Train maintenance personnel on proper maintenance procedures to avoid electrical hazards and accidents during servicing.

- Ventilation:Ensure adequate ventilation in the workspace to safely remove any fumes or heat generated during the curing process.

- UV Lamp Handling:Handle UV lamps with extreme care, following all safety guidelines provided by the manufacturer. Avoid touching lamps with bare hands and replace them as recommended.

- Monitoring:Continuously monitor the curing process, especially during the initial setup, to ensure that products are not overexposed to UV light, which can lead to material damage.

- Emergency Response:Establish clear emergency response procedures for incidents such as UV lamp failures, electrical malfunctions, or overheating.

- Regular Inspections:Conduct regular safety inspections of the UV Sole Activating Machineand its components to identify and address potential safety hazards.

Reviews

There are no reviews yet.