The EVA Compounding Line (Side Feeder) is a high-efficiency production system designed for precise mixing, melting, and compounding of EVA, PVC, TPR, and similar polymer materials. This advanced line is specially engineered with a side feeder system that ensures accurate and controlled addition of fillers, additives, and color masterbatches, resulting in superior compound uniformity and consistent quality.

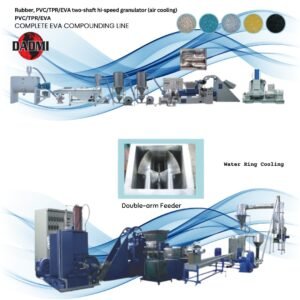

The line typically consists of a main extruder, side feeder, dosing units, heating and cooling systems, pelletizing or granulation unit, and a centralized control panel. The side feeder allows secondary materials to be introduced directly into the extrusion process at the optimal stage, improving dispersion, reducing material degradation, and enhancing overall compound performance.

Built with a robust structure and high-quality components, the EVA Compounding Line supports continuous operation with stable output and excellent energy efficiency. User-friendly controls enable precise temperature, speed, and feeding adjustments, while safety features ensure reliable and secure operation. The system is designed for low maintenance, long service life, and smooth production flow.

Widely used in footwear manufacturing for EVA sole compounds, slippers, sports shoes, and molded EVA products, this side feeder compounding line is an ideal solution for manufacturers seeking high productivity, flexibility in formulations, and consistently high-quality EVA compounds.

Reviews

There are no reviews yet.